Table of Contents

Introduction

The intent of SolidFit is to offer possible sizing solutions that are specific to your project application criteria. The information you provide will generate a preliminary list of solutions, allowing for comparisons between Rotary Valve Types and Sizes during the early stages of your project scope. Project (s) may be saved for future use, copied/edited or submitted for quotation. All quote requests require review by Meyer Sales Engineers before you are presented with an offer.

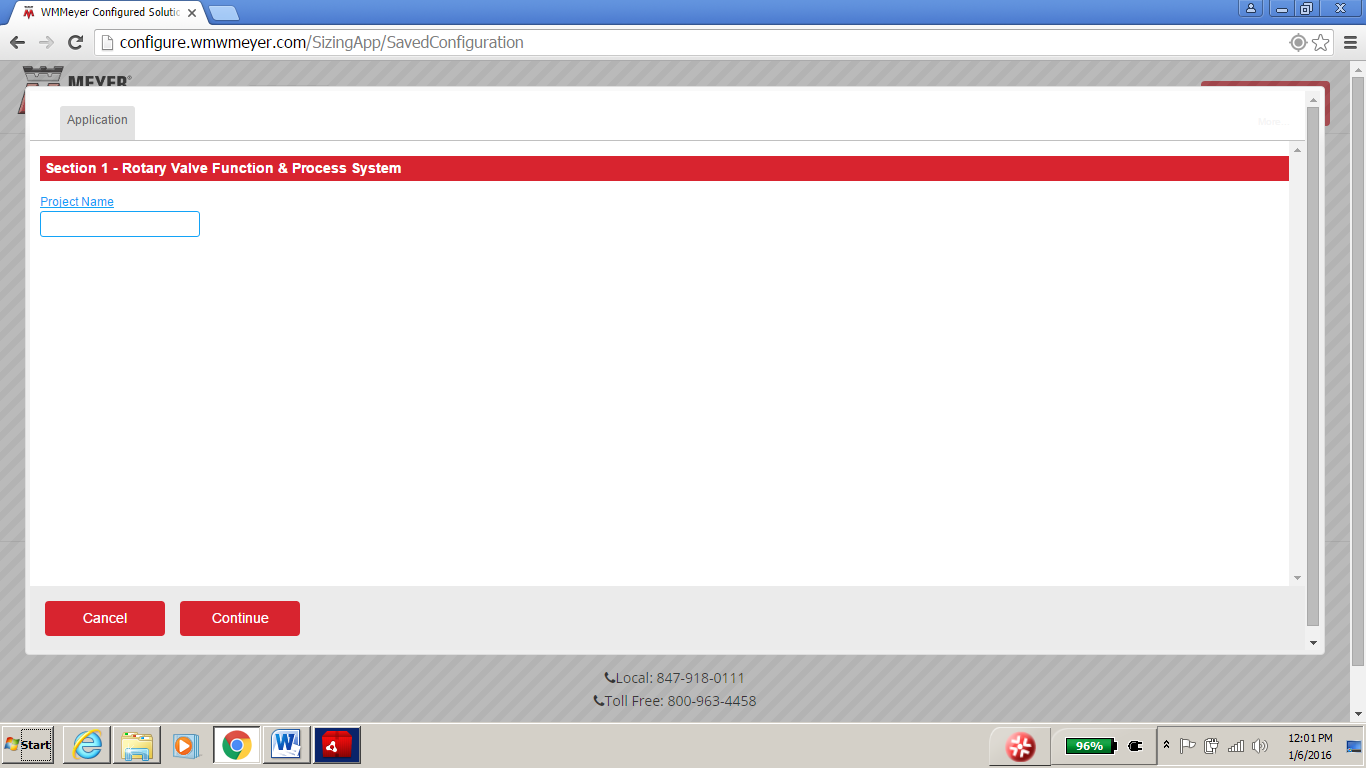

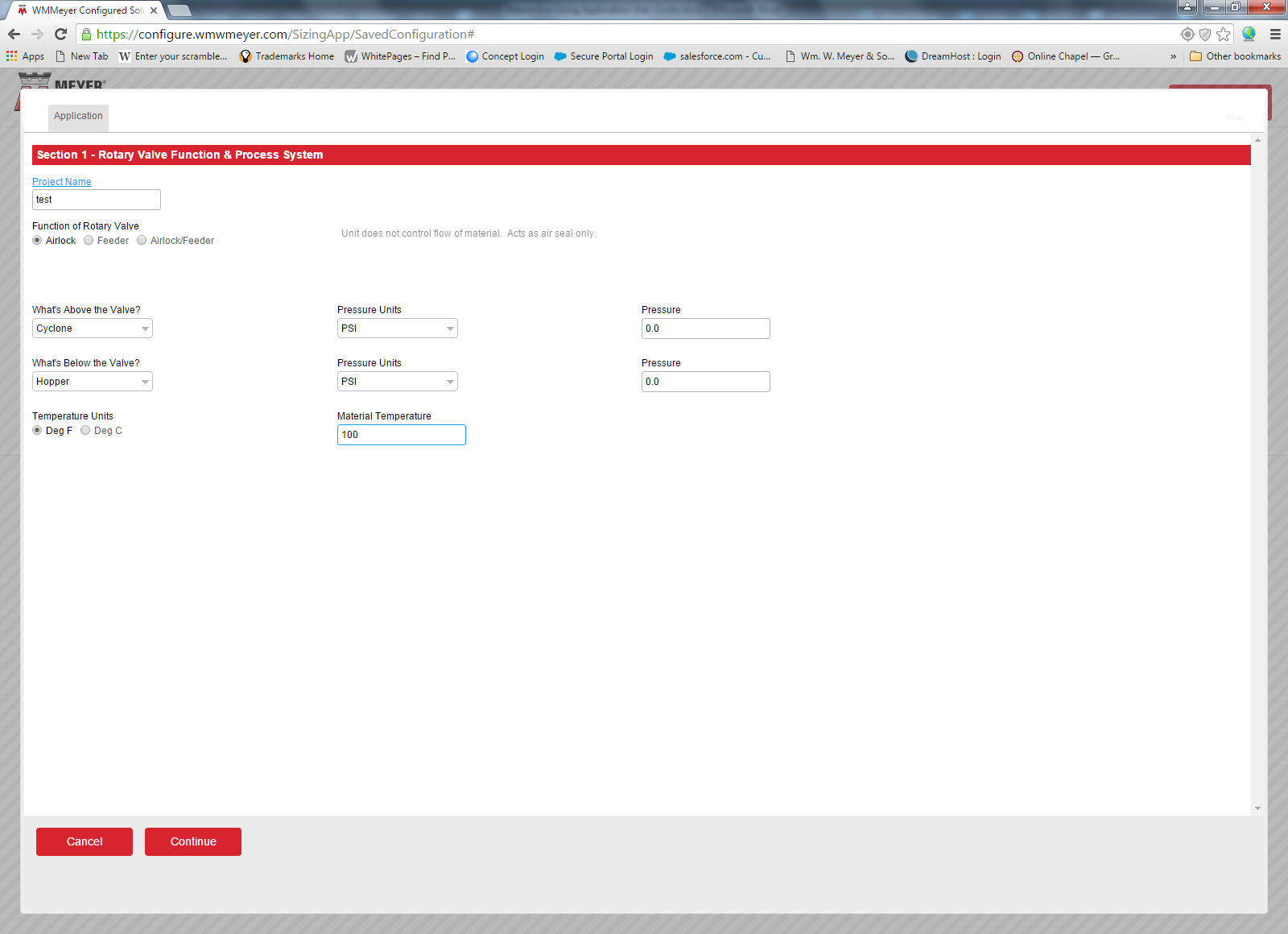

Section 1 — Rotary Valve Function & Process System

- Project Name — Enter a name to help you identify each of your projects, for example, Silo #5, Baghouse A, etc.

- Click Continue to advance to each set of questions.

-

Function of Rotary Valve — select one of the following:

- Airlock — Unit does not control flow of material. Acts as air seal online.

- Feeder — Unit controls flow of material. No significant pressure differential.

- Airlock/Feeder — Unit acts as air seal and controls flow of material.

- What's Above the Valve — select the type of device above the rotary valve.

-

Pressure:

- Pressure Units — select the unit of measurement of pressure (i.e. PSI, "W.C., "Hg, or Bar).

-

Pressure value — enter the pressure value based on your pressure units. Differential pressure > 10 PSI must be reviewed by Meyer.

Units Range PSI -14.7 to 15 " W.C. -406.8 to 419 " Hg -30 to 0 Bar -1 to 1.0

- What's Below the Valve — select the type of device below the rotary valve.

-

Pressure:

-

Pressure value — enter the pressure value based on your pressure units. Differential pressure > 10 PSI must be reviewed by Meyer.

Units Range PSI -14.7 to 15 " W.C. -406.8 to 419 " Hg -30 to 0 Bar -1 to 1.0

-

Pressure value — enter the pressure value based on your pressure units. Differential pressure > 10 PSI must be reviewed by Meyer.

-

Temperature

- Temperature units — specify Fahrenheit or Celsius

- Temperature of Material — Acceptable Operating temperatures are -25°F to 750°F, all others must be reviewed by Meyer.

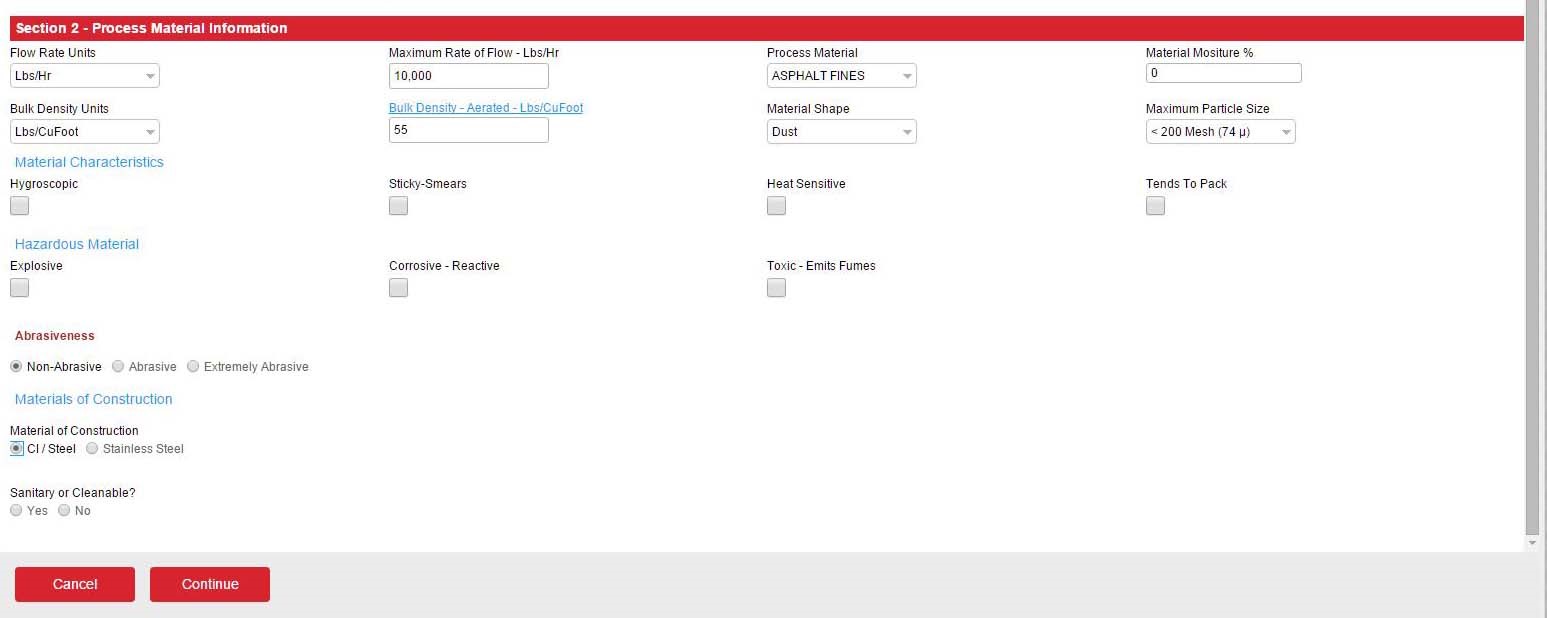

Section 2 — Process material Information

-

Flow Rate:

- Units — Specify the Flow Rate units of measurement (i.e. Lbs/Hr, Kg/Hr, Tons/Hr, Metric Tons/Hr.)

- Maximum Rate of Flow — Provide the numeric value of the flow rate.

- Process Material — from the dropdown menu select your material. Choose other if your material is not listed.

- Material Mosture % — Provide the percentage of moisture content of your material if known.

-

Bulk Density

- Units — pre-selected based on the Process Material above.

- Bulk Density- Aerated — Typical value shown based on the Process Material selected above. May be adjusged for your specific application.

- Material Shape — populated based on Process Material selection. Use dropdpwn to change selection if different.

- Maximum particle size — populated based on Process Material selection. Use dropdown to change selection if different.

- Material Characteristics — if known select all that apply.

- Hazardous Material — if known select all that apply

- Abrasiveness — level of the material's abrasiveness. A selection is required.

- Material of Construction — choice is defaulted based on information provided or selected above.

- Sanitary of Cleanable? — if your process equipment requires regular cleaning or sanitizing selecting YES will limit the possible Product solutions.

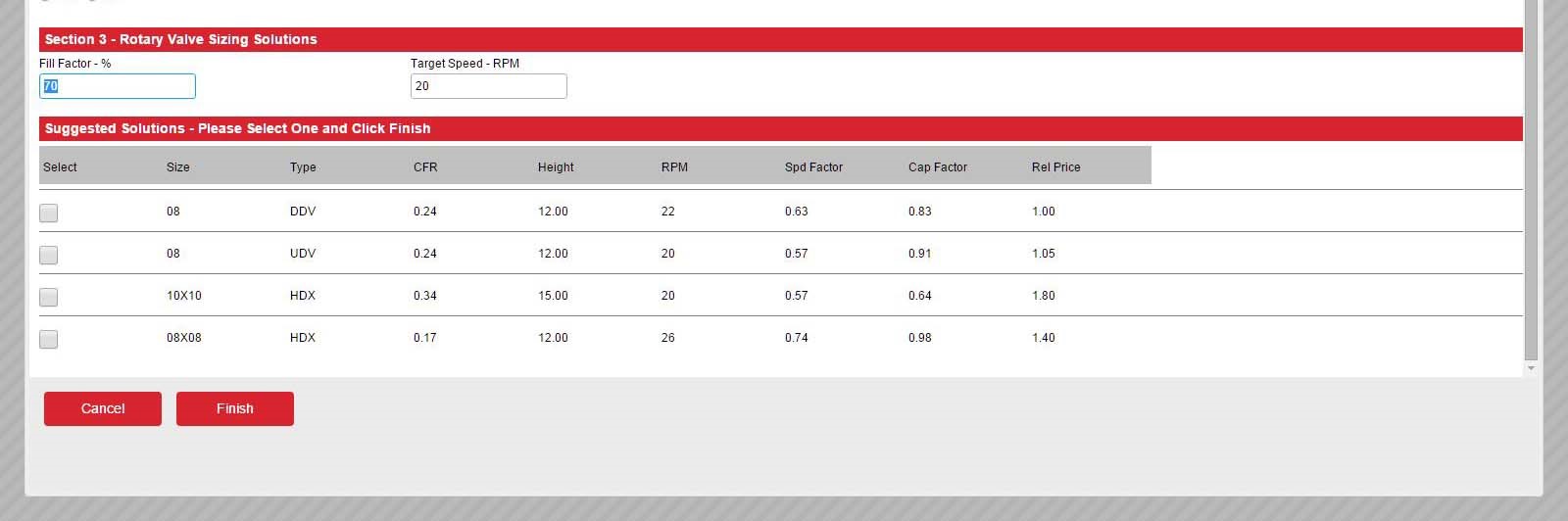

Section 3 — Rotary Valve Sizing & Suggested Solutions

-

Fill Factor % - Value is based on the function of the valve.

* Depending on ΔPFunction Range Airlock 50% to 70% * Feeder Up to 90% Airlock/Feeder 50% to 70% * - Target Speed — RPM — Populated value is based on material characteristics. User can overwrite value. Maximum limiting speed of 35 RPM depending on size of valve. Consult Meyer for more information.

- Suggested Solutions table — Solutions based on information provided. Listed by valve size, type, RPM, etc. Relative Price is based on basic offering. Final selection will be reviewed by Meyer.

- Select your choice of valve and click Finish to Save and proceed.

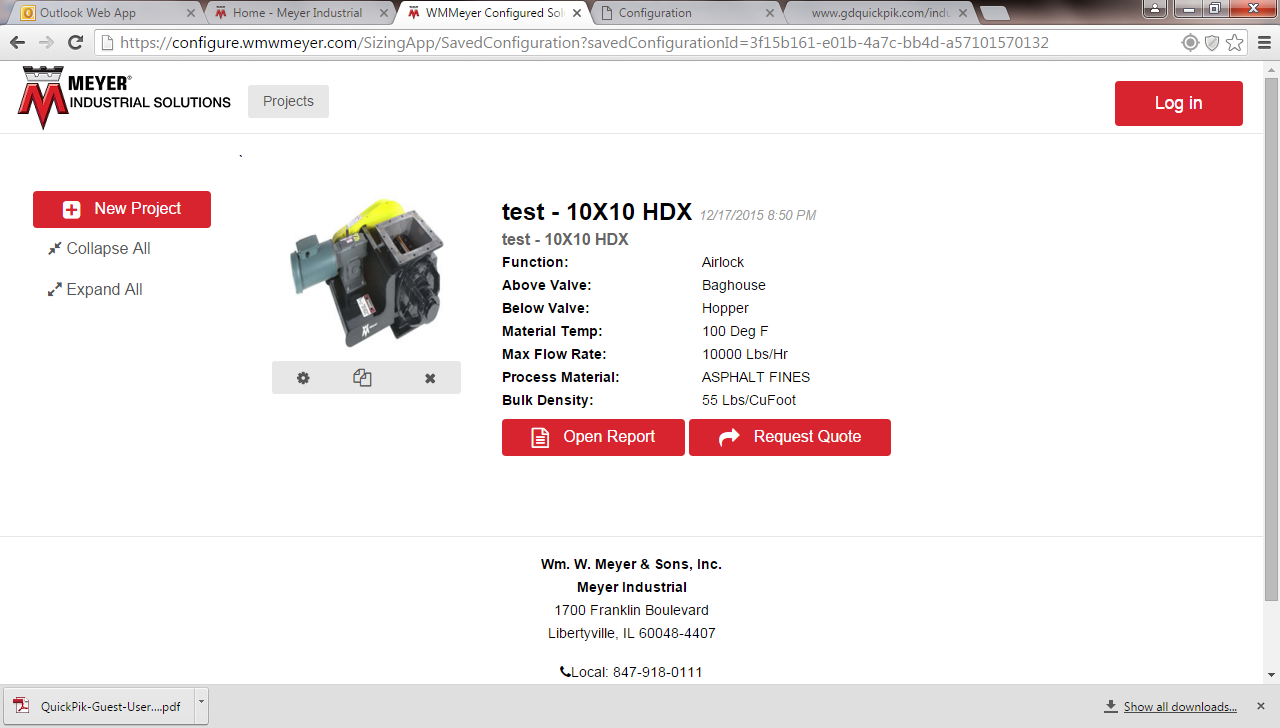

Project Summary

Your chosen valve and application summary is displayed.

Your chosen valve and application summary is displayed.

-

Product photo is representative of the model and not of the final configuration.

- Edit icon — allows you to enter the application and make changes to your selections.

- Copy icon — allows you to copy the aplication information and make any changes necessary.

- Delete icon — deletes the current item selected. To start over Select New Project.

- Open Report button — provides a PDF of the data entered and the listing of the Suggested Solutions.

- Request Quote button — Generates a request to Meyer for a Quote on the selected item. You will need to Register or Login if you have an account. See next section Registration — Login.

- New Project — returns to the program interface and you can create your next project.

- Collapse All — Click to hide product selection summary.

- Expand All — reveals product selection summary.

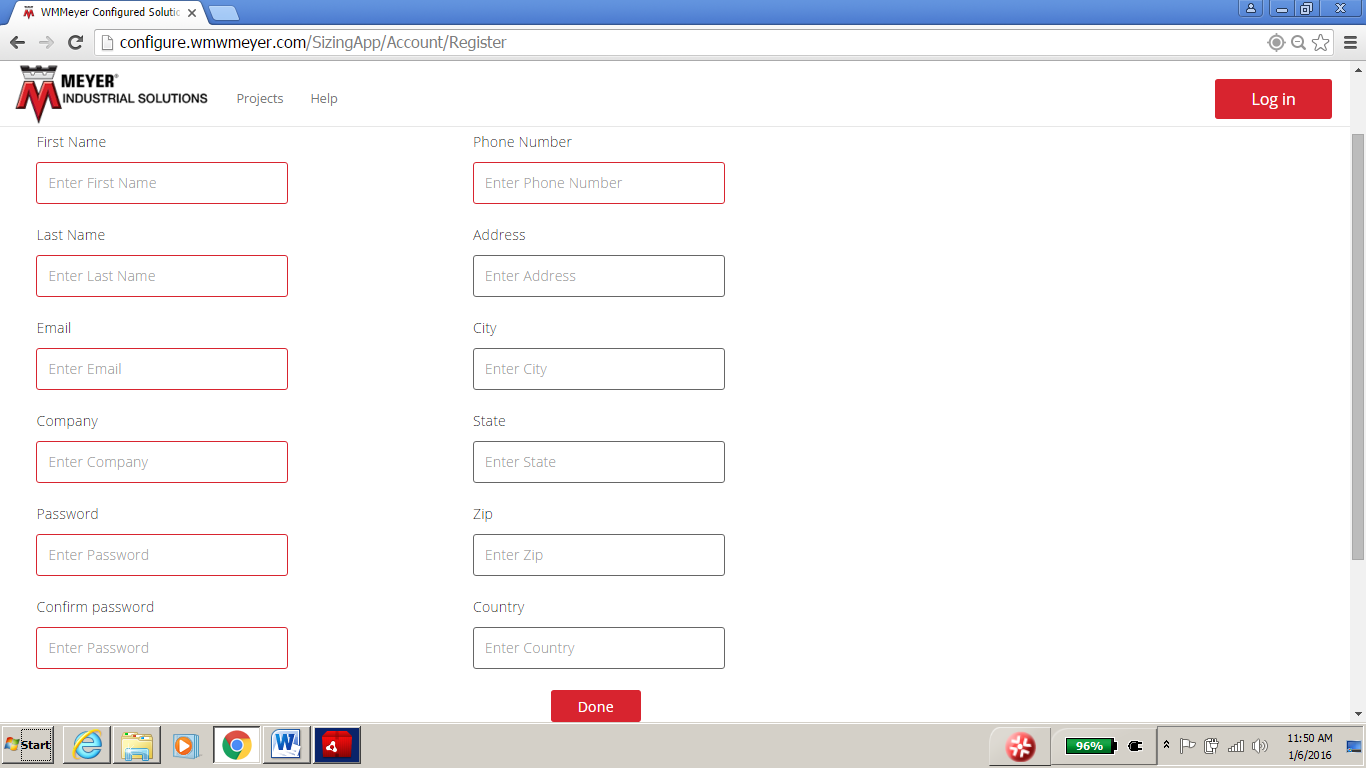

Request a Quote

- If you are a first time visitor to the site please register. Enter your information and click Submit.

- If you are a returning visitor, clik on Log In at the upper right corner and enter your email and password.